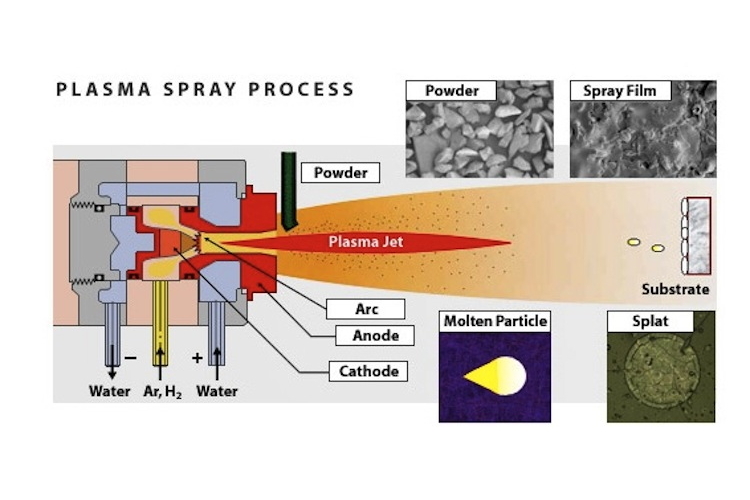

A

plasma spray torch includes nitrogen, hydrogen, or helium in some

cases, is permitted to stream between a water-cooled copper anode

and a tungsten cathode. An electric arc is started between the two

anodes through a high recurrence release and is then managed to

utilize a powder. The arc ionizes the gas, making high-pressure

plasma. The subsequent increment in gas temperature, which may

surpass 30,000°C, thus expands the gas volume and consequently its

pressure and speed as it leaves the nozzle. Gas speed, which may be

supersonic, must not be taken as molecule speed. In plasma splash

torch the power level range from 30 to 80 kW, reaching as big as 120

kW. Argon is generally picked as the foundation gas because it is

chemically inactive and has great ionization qualities. Including the

diatomic gasses, hydrogen or nitrogen can build the gas enthalpy. The

powder is generally brought into the gas flow either simply outside

the light or in a separating way out locale of the nozzle (anode).

The powder is warmed and quickened by the high-temperature,

high-speed gas plasma flow. Torchworking parameters and design are

vital in deciding the speed and temperature achieved by the powder

molecules. The working items incorporate not just gas stream, power

level, powder feed rate, and bearer gas flow, additionally the

separation from the substrate (standoff) to the torch and the

deposition angle. The standoff is of significant importance because

satisfactory separation must be accommodated warming and quickening

the powder, yet excessive separation will permit the powder to cool

and lose speed as the gas stream is quite chilling and moderating

off. The size and morphology of powder particles affects the rate of

warming and speeding up and thus, the effectiveness of testimony and

covering quality. As often as possible, a to some degree higher cost

for powder with more tightly size appropriation is more than adjusted

for by the enhanced deposition effectiveness. Powder speeds as plasma

splash deposition range from around 300 to 550 m/s. Temperatures are

frequently at the melting point or marginally above. By and large,

higher temperatures and molecule speeds over the melting point

however without extreme super-heating, yield coverings with the most

astounding densities and bond qualities.

A

plasma spray torch includes nitrogen, hydrogen, or helium in some

cases, is permitted to stream between a water-cooled copper anode

and a tungsten cathode. An electric arc is started between the two

anodes through a high recurrence release and is then managed to

utilize a powder. The arc ionizes the gas, making high-pressure

plasma. The subsequent increment in gas temperature, which may

surpass 30,000°C, thus expands the gas volume and consequently its

pressure and speed as it leaves the nozzle. Gas speed, which may be

supersonic, must not be taken as molecule speed. In plasma splash

torch the power level range from 30 to 80 kW, reaching as big as 120

kW. Argon is generally picked as the foundation gas because it is

chemically inactive and has great ionization qualities. Including the

diatomic gasses, hydrogen or nitrogen can build the gas enthalpy. The

powder is generally brought into the gas flow either simply outside

the light or in a separating way out locale of the nozzle (anode).

The powder is warmed and quickened by the high-temperature,

high-speed gas plasma flow. Torchworking parameters and design are

vital in deciding the speed and temperature achieved by the powder

molecules. The working items incorporate not just gas stream, power

level, powder feed rate, and bearer gas flow, additionally the

separation from the substrate (standoff) to the torch and the

deposition angle. The standoff is of significant importance because

satisfactory separation must be accommodated warming and quickening

the powder, yet excessive separation will permit the powder to cool

and lose speed as the gas stream is quite chilling and moderating

off. The size and morphology of powder particles affects the rate of

warming and speeding up and thus, the effectiveness of testimony and

covering quality. As often as possible, a to some degree higher cost

for powder with more tightly size appropriation is more than adjusted

for by the enhanced deposition effectiveness. Powder speeds as plasma

splash deposition range from around 300 to 550 m/s. Temperatures are

frequently at the melting point or marginally above. By and large,

higher temperatures and molecule speeds over the melting point

however without extreme super-heating, yield coverings with the most

astounding densities and bond qualities.Tuesday, 17 September 2019

Plasma Spray

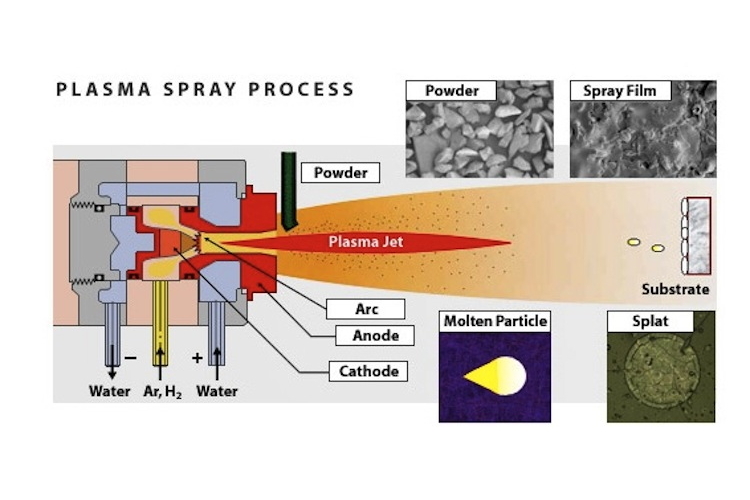

A

plasma spray torch includes nitrogen, hydrogen, or helium in some

cases, is permitted to stream between a water-cooled copper anode

and a tungsten cathode. An electric arc is started between the two

anodes through a high recurrence release and is then managed to

utilize a powder. The arc ionizes the gas, making high-pressure

plasma. The subsequent increment in gas temperature, which may

surpass 30,000°C, thus expands the gas volume and consequently its

pressure and speed as it leaves the nozzle. Gas speed, which may be

supersonic, must not be taken as molecule speed. In plasma splash

torch the power level range from 30 to 80 kW, reaching as big as 120

kW. Argon is generally picked as the foundation gas because it is

chemically inactive and has great ionization qualities. Including the

diatomic gasses, hydrogen or nitrogen can build the gas enthalpy. The

powder is generally brought into the gas flow either simply outside

the light or in a separating way out locale of the nozzle (anode).

The powder is warmed and quickened by the high-temperature,

high-speed gas plasma flow. Torchworking parameters and design are

vital in deciding the speed and temperature achieved by the powder

molecules. The working items incorporate not just gas stream, power

level, powder feed rate, and bearer gas flow, additionally the

separation from the substrate (standoff) to the torch and the

deposition angle. The standoff is of significant importance because

satisfactory separation must be accommodated warming and quickening

the powder, yet excessive separation will permit the powder to cool

and lose speed as the gas stream is quite chilling and moderating

off. The size and morphology of powder particles affects the rate of

warming and speeding up and thus, the effectiveness of testimony and

covering quality. As often as possible, a to some degree higher cost

for powder with more tightly size appropriation is more than adjusted

for by the enhanced deposition effectiveness. Powder speeds as plasma

splash deposition range from around 300 to 550 m/s. Temperatures are

frequently at the melting point or marginally above. By and large,

higher temperatures and molecule speeds over the melting point

however without extreme super-heating, yield coverings with the most

astounding densities and bond qualities.

A

plasma spray torch includes nitrogen, hydrogen, or helium in some

cases, is permitted to stream between a water-cooled copper anode

and a tungsten cathode. An electric arc is started between the two

anodes through a high recurrence release and is then managed to

utilize a powder. The arc ionizes the gas, making high-pressure

plasma. The subsequent increment in gas temperature, which may

surpass 30,000°C, thus expands the gas volume and consequently its

pressure and speed as it leaves the nozzle. Gas speed, which may be

supersonic, must not be taken as molecule speed. In plasma splash

torch the power level range from 30 to 80 kW, reaching as big as 120

kW. Argon is generally picked as the foundation gas because it is

chemically inactive and has great ionization qualities. Including the

diatomic gasses, hydrogen or nitrogen can build the gas enthalpy. The

powder is generally brought into the gas flow either simply outside

the light or in a separating way out locale of the nozzle (anode).

The powder is warmed and quickened by the high-temperature,

high-speed gas plasma flow. Torchworking parameters and design are

vital in deciding the speed and temperature achieved by the powder

molecules. The working items incorporate not just gas stream, power

level, powder feed rate, and bearer gas flow, additionally the

separation from the substrate (standoff) to the torch and the

deposition angle. The standoff is of significant importance because

satisfactory separation must be accommodated warming and quickening

the powder, yet excessive separation will permit the powder to cool

and lose speed as the gas stream is quite chilling and moderating

off. The size and morphology of powder particles affects the rate of

warming and speeding up and thus, the effectiveness of testimony and

covering quality. As often as possible, a to some degree higher cost

for powder with more tightly size appropriation is more than adjusted

for by the enhanced deposition effectiveness. Powder speeds as plasma

splash deposition range from around 300 to 550 m/s. Temperatures are

frequently at the melting point or marginally above. By and large,

higher temperatures and molecule speeds over the melting point

however without extreme super-heating, yield coverings with the most

astounding densities and bond qualities.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment