Threaded joints are the oldest method of joining piping systems. Thread cutting should be regarded as a precision machining operation. Typical threading die. For steel pipe, the lip angle should be about, but for brass, it should be much smaller. Improper lip angle results in rough or torn threads. Since pipe threads are not perfect, joint compounds are used to provide leak tightness. The compounds selected, of course, should be compatible with the fluid carried and should be evaluated for possible detrimental effects on system components. Manufacturers’ recommendations should be followed. Where the presence of a joint compound is undesirable, dry seal pipe threads in accordance with ASME B1.20.346 may be employed. These are primarily found in hydraulic and pneumatic control lines and instruments. Flanged joints are most often used where disassembly for maintenance is desired. A great deal of information regarding the selection of flange types, flange tolerances, facings and gaskets, and bolting is found in B16.5. The limitations regarding cast iron-to-steel flanges, as well as gasket and bolting selection, should be carefully observed. The governing code will usually have further requirements. Gasket surfaces should be carefully cleaned and inspected prior to making up the joint. Damaged or pitted surfaces may leak. Appropriate gaskets and bolting must be used. The flange contact surfaces should be aligned perfectly parallel to each other. Attempting to correct any angular deviation perpendicular to the flange faces while making up the joint may result in overstressing a portion of the bolts and subsequent leakage. The proper gasket should be inserted making sure that it is centred properly on the contact surfaces. Bolts should be tightened hand-tight. If necessary for alignment elsewhere, the advantage may be taken of the bolt hole tolerances to translate or rotate in the plane of the flanges. In no case should rotation perpendicular to the flange faces be attempted? When the assembly is in its final location, bolts should be made up wrench-tight in a staggered sequence. The bolt loading should exert a compressive force of about twice that generated by the internal pressure to compensate not only for internal pressure but for any bending loads which may be imposed on the flange pair during operation. For a greater guarantee against leakage, torque wrenches may be employed to load each bolt or stud to some predetermined value. Care should be exercised to preclude loading beyond the yield point of the bolting. In other cases, special studs that have had the ground of the end to permit micrometre measurement of stud elongation may be used. Flange pairs which are to be insulated should be carefully selected since the effective length of the stud or bolt will expand to a greater degree than the flange thicknesses, and leakage will occur. Thread lubricants should be used, particularly in high-temperature service to permit easier assembly and disassembly for maintenance.

Thursday, 17 October 2019

Friday, 11 October 2019

Construction of Pipeline

Designing

and constructing a pipeline is a major undertaking, requiring a wide

variety of engineering and construction skills. A large pipeline the operator would have the internal resources (both trained and

experienced manpower and equipment) to undertake all phases of

pipeline construction, it is more likely that virtually all of the

major phases of construction will be contracted out to companies

possessing the necessary expertise and capacities to complete the

task. While that guarantees the critical requirements of the pipeline

construction will be met, it also introduces the need to control

logistics to ensure that all contractor activities are coordinated

and not mutually exclusive of one another. Construction can take

place because pipeline construction equipment is distributed along

the pipeline route in a moving assembly line in which only one major

item of construction equipment is normally needed at any one point of

time. The distance along the pipeline over which this equipment is

deployed is relatively shorter and less than a mile, but there may be

several sets of construction equipment operational along the pipeline

route at any given time. The complete set of equipment — for

ditching, welding, coating, lowering in, and backfilling are called

spreads. A single pipeline may be built using several spreads,

reducing the overall construction period, but also increasing the number of people and secondary resources required to support them.

Large pipeline projects can also be divided into two or more

segments, and different construction contractors may be used to

install each segment. Various construction activities also take place

simultaneously on a number of segments. Each of these contractors may

field several spreads to build a segment. The actual installation of

the pipeline includes these major steps:

1. clearing the ROW as

needed.

2. Ditching.

3. Stringing pipe joints along the ROW.

4.

Welding the pipe joints together.

5. Applying a coating and wrapping

the exterior of the pipe (except for the portions of the pipe at

each end, which is sometimes coated before being delivered to the job

site).

6. Lowering the pipeline into the ditch.

7. Backfilling the

ditch.

8. Testing the line for leaks.

9. Cleanup and drying the

pipeline after testing to prepare it for operation.

10. Reclaiming

impacted environmental areas.

Thursday, 3 October 2019

Visual Testing

Visual

inspection (VT) refers to the detection of surface imperfections

using the eye. Usually being applied without any kind of additional

equipment, VT can be improved by using aids such as a magnifying

glass to improve its effectiveness and scope. VT is one of the

primary NDT methods. Since it relies on an evaluation made using the

eye, VT is generally considered to be the primary and oldest method

of NDT. Due to the relative simplicity and as it does not require

sophisticated apparatus, it is a very inexpensive method thus

provides an advantage over other NDT methods. VT is an ongoing

inspection that can be applied at various stages of construction. The

primary limitation of VT is it is only capable of evaluating

discontinuities, which can be seen on the surface of the material or

part. On several occasions, there are some visual indications of a

subsurface imperfection that may need an additional NDT method to

provide verification of the subsurface discontinuity. VT is often

taken to be effective when it is performed at all stages of any new

fabrication and is the main method used during the inspection of

pressure equipment. If applied after welding has been completed, it

is possible that subsurface flaws may not be detected. Thus it can be

said that VT will only be fully effective if it is applied throughout

any fabrication or inspection. An effective VT that is applied at the

correct time will detect most defects or discontinuities that may

later be found by some other costly and time-consuming NDT method. A

flaw, such as incomplete fusion at the weld root, can be repaired

easily and quickly right after it is produced, saving on expense and

time required repairing it after the weld has been inspected using

some other NDT technique. VT provides immediate information on the

condition of pressure equipment regarding such things as corrosion,

bulging, distortion, correct parts, failures, etc. VT requires three

basic conditions to be in place. Good vision: to be able to see what

we are looking for, good lighting: the correct type of light is

important & experience: to be able to recognize problems. As

mentioned previously, one of the advantages of VT is that there is

little or no equipment required, which improves its economy or

portability. Equipment so as to improve the accuracy, repeatability,

reliability, and efficiency of VT, include various devices.

Magnifying glasses can also be used for a more detailed look at some

visual feature. As such proper care must be taken to avoid making

erroneous decisions regarding the size or extent of some

discontinuity when its image is magnified.

Thursday, 26 September 2019

Demagnetization

Demagnetization

is possible in different ways. One of the most common is to subject

the magnetized part to a magnetizing force that continually reverses

its direction while it is gradually decreasing in strength. As the

decreasing magnetizing force is applied, first in one direction and

then in the opposite direction, the residual magnetization of the

part is decreased. Generally, a high-intensity demagnetizer is used.

The demagnetization is most common but does not demagnetize as deep

or complete as a DC step down unit. This decreasing magnetization is

accomplished by smaller and smaller hysteresis loops created by the

application of decreasing current. A smaller and narrower loop shows

lower residual magnetism. All steels have a certain amount of

coercive force, making it extremely difficult if not impossible to

demagnetize them completely. The only way to completely demagnetize

some materials is to heat them to their Curie point or above. Under

normal conditions, a part is considered to be satisfactorily

demagnetized if, when checked with a field indicator, the magnetic

field is below minimum limits. The Code requires demagnetization when

the residual field in the part:

Demagnetization

is possible in different ways. One of the most common is to subject

the magnetized part to a magnetizing force that continually reverses

its direction while it is gradually decreasing in strength. As the

decreasing magnetizing force is applied, first in one direction and

then in the opposite direction, the residual magnetization of the

part is decreased. Generally, a high-intensity demagnetizer is used.

The demagnetization is most common but does not demagnetize as deep

or complete as a DC step down unit. This decreasing magnetization is

accomplished by smaller and smaller hysteresis loops created by the

application of decreasing current. A smaller and narrower loop shows

lower residual magnetism. All steels have a certain amount of

coercive force, making it extremely difficult if not impossible to

demagnetize them completely. The only way to completely demagnetize

some materials is to heat them to their Curie point or above. Under

normal conditions, a part is considered to be satisfactorily

demagnetized if, when checked with a field indicator, the magnetic

field is below minimum limits. The Code requires demagnetization when

the residual field in the part:

• Could

interfere with subsequent processing or usage such as machining

operations where chips will adhere to the surface of the part of the

tip of a tool may become magnetized from contact with the magnetized

part. Such chips involve in smooth cutting by the tool adversely

affecting both finish and tool life. Other reasons to demagnetize

would be in cases where residual magnetism:

• May

interfere with electric arc welding operations. Residual magnetic

fields may deflect the arc away from the point at which it should be

applied.

• May

interfere with the functioning of the part itself, after it is placed

into service. Magnetized tools, such as milling cutters, hobs, etc.,

may hold chips and cause rough surfaces, and may even be broken by

adherent chips at the cutting edge.

• Moving

parts, especially in the oil, may hold particles; for instance, on

balls or races of ball bearings, or gear teeth causing wear.

•capable

of holding particles that interfere with later applied coatings such

as plating or paint. Demagnetization may not be required where:

• Part

material is low carbon steel and has low retentivity.

• The

material consists of structural parts such as weldments, large

castings, boilers, etc., where the presence of a residual field would

have little or no effect on the proper performance of the part.

• The the part is to be subsequently processed or heat-treated and in the

process will become heated above its Curie point or about 770 °C

(1390°F) for steel.

• Apart

is to be subsequently re-magnetized in another direction to the same

or higher level at which it was originally magnetized as, for

example, between the steps of circular and longitudinal magnetizing,

for MT purposes.

Tuesday, 17 September 2019

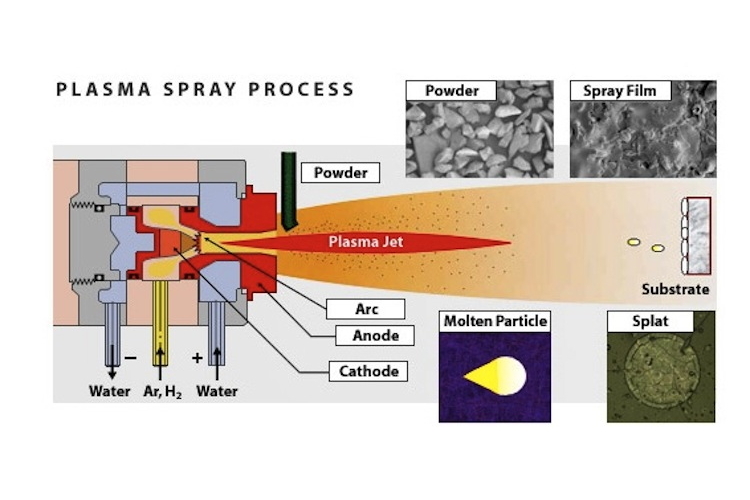

Plasma Spray

A

plasma spray torch includes nitrogen, hydrogen, or helium in some

cases, is permitted to stream between a water-cooled copper anode

and a tungsten cathode. An electric arc is started between the two

anodes through a high recurrence release and is then managed to

utilize a powder. The arc ionizes the gas, making high-pressure

plasma. The subsequent increment in gas temperature, which may

surpass 30,000°C, thus expands the gas volume and consequently its

pressure and speed as it leaves the nozzle. Gas speed, which may be

supersonic, must not be taken as molecule speed. In plasma splash

torch the power level range from 30 to 80 kW, reaching as big as 120

kW. Argon is generally picked as the foundation gas because it is

chemically inactive and has great ionization qualities. Including the

diatomic gasses, hydrogen or nitrogen can build the gas enthalpy. The

powder is generally brought into the gas flow either simply outside

the light or in a separating way out locale of the nozzle (anode).

The powder is warmed and quickened by the high-temperature,

high-speed gas plasma flow. Torchworking parameters and design are

vital in deciding the speed and temperature achieved by the powder

molecules. The working items incorporate not just gas stream, power

level, powder feed rate, and bearer gas flow, additionally the

separation from the substrate (standoff) to the torch and the

deposition angle. The standoff is of significant importance because

satisfactory separation must be accommodated warming and quickening

the powder, yet excessive separation will permit the powder to cool

and lose speed as the gas stream is quite chilling and moderating

off. The size and morphology of powder particles affects the rate of

warming and speeding up and thus, the effectiveness of testimony and

covering quality. As often as possible, a to some degree higher cost

for powder with more tightly size appropriation is more than adjusted

for by the enhanced deposition effectiveness. Powder speeds as plasma

splash deposition range from around 300 to 550 m/s. Temperatures are

frequently at the melting point or marginally above. By and large,

higher temperatures and molecule speeds over the melting point

however without extreme super-heating, yield coverings with the most

astounding densities and bond qualities.

A

plasma spray torch includes nitrogen, hydrogen, or helium in some

cases, is permitted to stream between a water-cooled copper anode

and a tungsten cathode. An electric arc is started between the two

anodes through a high recurrence release and is then managed to

utilize a powder. The arc ionizes the gas, making high-pressure

plasma. The subsequent increment in gas temperature, which may

surpass 30,000°C, thus expands the gas volume and consequently its

pressure and speed as it leaves the nozzle. Gas speed, which may be

supersonic, must not be taken as molecule speed. In plasma splash

torch the power level range from 30 to 80 kW, reaching as big as 120

kW. Argon is generally picked as the foundation gas because it is

chemically inactive and has great ionization qualities. Including the

diatomic gasses, hydrogen or nitrogen can build the gas enthalpy. The

powder is generally brought into the gas flow either simply outside

the light or in a separating way out locale of the nozzle (anode).

The powder is warmed and quickened by the high-temperature,

high-speed gas plasma flow. Torchworking parameters and design are

vital in deciding the speed and temperature achieved by the powder

molecules. The working items incorporate not just gas stream, power

level, powder feed rate, and bearer gas flow, additionally the

separation from the substrate (standoff) to the torch and the

deposition angle. The standoff is of significant importance because

satisfactory separation must be accommodated warming and quickening

the powder, yet excessive separation will permit the powder to cool

and lose speed as the gas stream is quite chilling and moderating

off. The size and morphology of powder particles affects the rate of

warming and speeding up and thus, the effectiveness of testimony and

covering quality. As often as possible, a to some degree higher cost

for powder with more tightly size appropriation is more than adjusted

for by the enhanced deposition effectiveness. Powder speeds as plasma

splash deposition range from around 300 to 550 m/s. Temperatures are

frequently at the melting point or marginally above. By and large,

higher temperatures and molecule speeds over the melting point

however without extreme super-heating, yield coverings with the most

astounding densities and bond qualities.Friday, 13 September 2019

Cold Pressure Welding

(a) the difference on a micro-scale of the local plastic strain occurring on matching opposite faces of the weld interface

(b) relative hardness of the metal and its oxide film, and

(c) mechanical properties of the oxide.

The second stage involves:

(a) plastic flow of the metal to the over-lapped areas; the stress at which this can take place is influenced by the stacking fault energy of the metal

(b) some relative shear displacement at the points where metal cleaned of oxide comes into contact; this is influenced by surface roughness Cold pressure welding is used for joining of aluminium cables, various kitchen furniture, electrolysis cells, communication lines, for joining wires and rods, production of heat exchangers at coolers and application of joining different materials nowadays. Various researchers carried some of the studies about cold pressure welding out: gave knowledge about investigations on pressure welding and cold pressure welding. [3] Investigated the mechanism of solid-state pressure welding. Examined the bonding mechanism of cold pressure welding. [5] Investigated cold pressure welding of aluminium and copper by butt upsetting. [6] Investigated effects on welding strength of process parameters in cold pressure welding of aluminium. [7] Obtained the surface roughness depending on welding strength in cold pressure welding of aluminium. [8] Directed the process parameters optimization for obtaining high weld strength in cold solid-state joining of sintered steel and copper powder metallurgical performs. The knowledge about the cold pressure welding method and the developments in its applications were given in this study. Then, as for example, cold pressure welding was applied on commercial purity aluminium alloy sheets as lap welding. 150 metric ton hydraulic press was used for the welding process. Before welding, the wire-brushing process was applied for preparing aluminium sheets, which are test parts, the roughness was determined with surface roughness equipment and afterwards, deformation was applied at different deformation ratios. Then, the microstructure of the welded parts at a given welding deformation was examined, and it was researched that whether joints were properly obtained or not. Then, the results were commented.

Tuesday, 3 September 2019

What is RT?

RT

is a volumetric examination method used for examining the entire

specimen rather than just the surface. It is the historical

approach to examine completed welds for surface and

subsurface discontinuities. The method uses the change in

absorption of radiation by solid metal and areas of a

discontinuity. The radiation transmitted reacts with the film, a

latent image is captured, and when the film is processed (developed)

creates a permanent image (radiograph) of the weld. Some methods are

available which use electronics to create a digital image and are

referred to as “filmless.” Due to the hazard of radiation, and

the licensing requirements, the cost can be higher and the trained

and certified personnel more limited, than with other NDE methods. An

NDT examiner interprets and evaluates the radiographs for differences

in absorption and transmission results. Radiographic indications show

a different density in comparison with the normal background image of

the weld or part being inspected. The radiographer also makes sure

that the film is exposed by the primary source of the radiation and

not backscatter radiation. The NDT examiner that performs the film

interpretation, evaluation and reporting should be certified as a

minimum to ASNT Level II requirements. However, all personnel

performing radiography are required to attend radiation safety

training and comply with the applicable regulatory requirements. There

are very specific requirements about the quality of the produced

radiograph, including the sharpness of the image, the ability to

prove adequate film density in the area of interest and sensitivity

to the size and type of expected flaws. The requirements include:

- Method to determine if backscatter is present.

- Permanent identification, traceable to the component.

- Film selection under SE-1815.

- Different designations for hole or wire-type image quality indicators (penetrameters).

- Suggested radiographic techniques.

- Facilities for viewing radiographs.

Calibration (certification of source size). The exposure and processing of a radiograph are considered acceptable when it meets the required quality features in terms of sensitivity and density. These factors are designed to ensure that imperfections of a dimension relative to section thickness will be revealed. Standards for industrial radiography require the use of one or more image quality indicators (IQIs) to determine the required sensitivity is achieved. The IQI that was previously known as penetrameter is no longer being used in most codes. To assess sensitivity the required hole or wire as specified by the governing code must be visible on the finished radiograph. Mistakes with IQIs (penetrameters) can have a much greater impact on thinner wall pipe where large root pass imperfections can significantly reduce the strength and integrity of a weld. IQIs (penetrameters) are tools used in industrial radiography to establish the quality level of the radiographic technique

Subscribe to:

Posts (Atom)